How sustainable materials are shaping EV production and cutting emissions

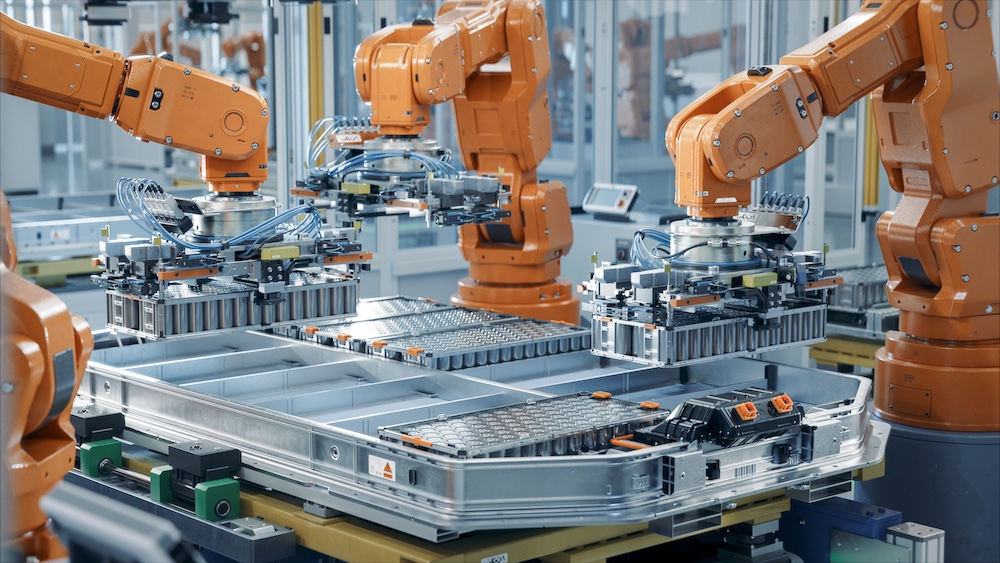

EV production is the process of manufacturing electric vehicles, from sourcing materials to battery assembly. Sustainable EV production helps improve manufacturing efficiency, cut emissions and support a circular economy across the automotive supply chain by using recycled plastics, bio-based composites and renewable energy.

Global demand for electric vehicles (EVs) is accelerating at pace. But as production volumes grow, the focus of scrutiny is shifting. Tailpipe emissions are no longer the only measure of progress – EV production itself is in the spotlight. How do manufacturers reduce the environmental impact of building electric vehicles while still delivering the performance, affordability and scale the market demands?

For OEMs, supply chain managers, and fleet operators, this is a pressing challenge, one that could define the industry’s credibility in the eyes of the consumer.

One of the most powerful levers available is material innovation. By rethinking what EVs are made from – whether it’s recycled plastics, bio-based composites, or lightweight alloys – manufacturers can cut production emissions, improve efficiency, and move closer to a circular economy.

What is sustainable EV production?

At its simplest, EV production encompasses the entire process of manufacturing an electric vehicle: from the extraction of raw materials to EV battery production and assembly on the factory floor. For EV production to be sustainable, it means embedding environmental responsibility into every stage.

According to the International Energy Agency (IEA), producing an EV can generate 40–60% more emissions than building a petrol or diesel car, primarily due to battery manufacturing and material processing. That figure can’t be ignored. However, over the vehicle’s lifecycle the emissions are less than ICE vehicles, with actions taken at production to reduce the impact.

Sustainable EV production focuses on three principles:

- Substituting carbon-intensive inputs with sustainable materials

- Building a green supply chain with traceable, responsibly sourced inputs

- Designing for manufacturing efficiency, repairability and recyclability from day one

Sustainable materials transforming EV production

Materials are central to reducing emissions in EV production. Traditional plastics, steel, and aluminium are carbon-intensive to produce and often difficult to recycle. In contrast, new approaches are emerging that both reduce production emissions and enhance vehicle efficiency.

Recycled plastics

Plastics are everywhere in vehicles – dashboards, trims, underbody parts. Traditionally, they’ve been petroleum-based, but more OEMs are committing to minimum recycled content targets.

The business case is compelling: recycled plastics reduce reliance on virgin petroleum-based materials, cut emissions from production, and meet rising regulatory and ESG expectations. Ford’s wiring clips made from ocean plastics are a small but telling example – proof that even non-glamorous parts of the vehicle can drive sustainability.

Bio-based composites

Plant-based fibres like hemp, flax and kenaf are moving from niche to mainstream. They’re often durable, renewable, and lightweight, reducing vehicle mass and therefore improving efficiency.

Mercedes-Benz has already trialled bio-based seat fabrics and trims, while smaller innovators are developing biodegradable composites that could replace glass fibre in semi-structural parts. This not only improves the vehicle’s sustainability credentials but also provides performance gains that extend battery range.

Lightweight alloys

Weight matters much more with an electric vehicle. Lower weight often means more range, and every 100kg cut can extend driving range by 6–8%. That’s why Tesla, Jaguar Land Rover and others have leaned heavily into aluminium and magnesium alloys for body structures and battery housings.

Recycled aluminium, in particular, is a game-changer: producing it uses up to 95% less energy than primary aluminium.

EV production emissions and environmental impact

While EVs have clear benefits over ICE vehicles during use, EV production emissions remain a significant concern. Generally, EVs produce more CO₂ than a petrol or diesel equivalent, largely due to battery production and materials processing. Battery cells, aluminium, steel and plastics together account for the majority of an EV’s embedded carbon footprint, whilst battery longevity remains a key concern for many consumers.

But here’s the opportunity: each of these hotspots can be mitigated.

- Battery cells: decarbonising cell factories with renewable energy can slash their footprint.

- Aluminium and steel: recycled alloys drastically cut emissions compared to virgin metals.

- Plastics and composites: substituting virgin with recycled content reduces production emissions by 30–50%.

- Battery longevity: embed a repair-first mindset for batteries to maximise the life and value of materials already in the system.

UK EV battery production

As demand grows, the UK automotive sector is doubling down on domestic battery cell production through strategic gigafactory projects. These investments are crucial to reducing embedded emissions, strengthening local value chains and meeting regulatory and ESG expectations.

Two major projects stand out:

1. AESC Sunderland Gigafactory – Expected to open in 2025 with an initial 12 GWh capacity, scalable to 35 GWh. Powered by net-zero energy and integrated with Nissan’s nearby assembly lines, it cuts both emissions and logistics costs.

2. Tata / Agratas Gigafactory, Somerset – A £4 billion investment delivering 40 GWh capacity from 2026. As one of Europe’s largest gigafactories, it will meet half of UK demand by 2030 and anchor Jaguar Land Rover’s EV future.

Together, these facilities represent over 50 GWh of secured UK capacity by 2030. More than factories, they are symbols of how localised production, renewable energy, and recycling commitments can combine to cut EV production emissions while boosting national competitiveness.

The Faraday Institution projects the UK will need six such gigafactories by 2030. The message is clear: the race is on, and sustainability will be the differentiator.

Preparing for a sustainable EV production future

So how should manufacturers respond? It’s not enough to “wait and see” – because drivers, regulators, and investors are already setting higher expectations.

Here are the immediate steps that can turn sustainability into a strategy:

1. Increase recycled content – Secure supply of recycled plastics and alloys before demand outstrips availability.

2. Invest in bio-based innovation – Don’t just pilot, but scale. Bio composites will be integral for the interiors of the future.

3. Cut battery emissions at source – Work with suppliers on renewable energy integration and closed-loop battery repair and recycling.

4. Lead with sustainability in messaging – ESG performance is no longer background detail, it’s a selling point.

By taking these steps, OEMs can align with regulatory expectations, support the circular economy, and drive long-term manufacturing efficiency.

Conclusion: Sustainable EV production

The future of EV production will be measured not just in volumes, but in emissions avoided. Sustainable materials – from recycled plastics and bio-based composites to lightweight alloys – are already reshaping manufacturing strategies.

While challenges remain – particularly around EV battery production – early adopters of sustainable materials are already seeing benefits in terms of carbon footprint reduction, cost savings, and supply chain resilience.

For OEMs, supply chain leaders, and fleet operators, embracing sustainable materials is not only about cutting emissions. It is about securing a competitive edge in an increasingly sustainability-driven market.

Cox Automotive will continue to provide insights into EV production, battery sustainability, and the future of green mobility. Explore more on our EV Hub.

EV production FAQs

What is EV production?

EV production covers every stage of manufacturing an electric vehicle, from sourcing materials to assembly. Sustainable EV production integrates low-carbon materials and renewable energy to reduce emissions.

Are EV production emissions higher than petrol or diesel cars?

Yes. EV production emissions are higher than ICE vehicles, due to battery manufacturing and material processing. However, data shows that over the vehicle lifecycle, EVs product fewer total emissions, especially when powered by clean energy.

How is the UK improving EV production sustainability?

UK EV production is advancing, with new gigafactories like AESC Sunderland and Tata Agratas Somerset, which are both powered by renewable energy. Projects like these support localised supply chains, reduce logistics emissions and strengthens national competitiveness.

What sustainable materials are used in EV production?

More manufacturers are using recycled plastics, bio composites and lightweight alloys to lower carbon footprints. These sustainable materials boost energy efficiency and help create a circular economy in automotive manufacturing.

How do OEMs reduce EV battery production emissions?

OEMs are decarbonising EV battery production with renewable power, increased recycled material content and closed-loop recycling. Improving manufacturing efficiency to achieve long-term decarbonisation goals.